The stamping and cutting industry is continuously evolving. To stay competitive, professionals must keep up with the latest trends and innovations. In 2024, several technological and methodological advances will transform the sector. Here’s an overview of the main trends to watch this year.

1. Increased Automation and Robotics

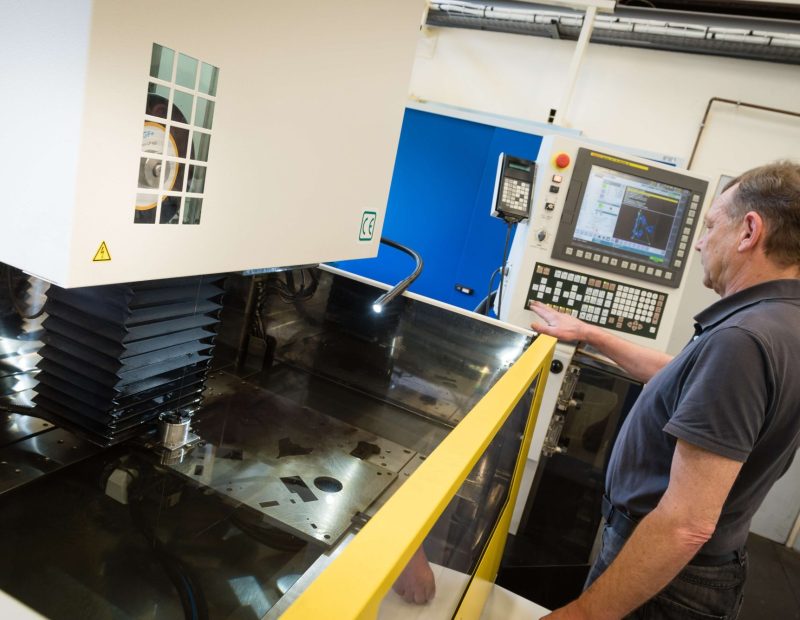

Automation continues to revolutionize the stamping and cutting process. Companies are adopting automated solutions to enhance precision, reduce costs, and boost productivity. Robots are increasingly used for repetitive and hazardous tasks, allowing human operators to focus on more complex operations.

2. Advanced Materials

The use of advanced materials, such as lightweight alloys and composites, is on the rise. These materials offer superior strength and flexibility, crucial for modern industrial applications. Innovations in materials also help reduce component weight, contributing to energy efficiency and the sustainability of finished products.

3. Digital Simulation and Modeling

Digital simulation and modeling tools are becoming increasingly sophisticated. They accurately predict the outcomes of stamping and cutting processes, reducing the need for physical prototypes and associated costs. This technology also helps optimize production parameters for maximum efficiency.

4. High-Precision Cutting Techniques

Techniques such as laser and water jet cutting are becoming more precise and efficient. These methods enable complex and fine cuts, essential for industries requiring high precision, such as aerospace and electronics. 2024 is likely to see broader adoption of these advanced technologies.

5. Integration of IoT (Internet of Things)

IoT integration in stamping and cutting processes enables real-time monitoring and analysis of operations. IoT sensors collect valuable data on machine performance, helping prevent breakdowns and optimize processes. This trend will continue to grow with advances in connectivity and data analysis technologies.

6. Additive Manufacturing and Stamping

Additive manufacturing, or 3D printing, is beginning to play a complementary role in stamping and cutting. It enables quick and cost-effective production of customized tools and dies. This flexibility is particularly beneficial for small series and prototypes.

7. Ecology and Sustainability

Environmental concerns are also influencing the sector. Companies are seeking ways to reduce their carbon footprint and minimize waste. Process optimization and the use of recyclable materials are key aspects of this trend. Innovations in stamping and cutting increasingly incorporate these ecological considerations.

8. Training and Skills Development

The rapid evolution of stamping and cutting technologies necessitates continuous training for operators and engineers. Companies are increasingly investing in training programs to ensure their staff stay proficient in the latest innovations and techniques. Online courses, hands-on workshops, and collaborations with research institutes are becoming common to maintain high skill levels.

9. Industry Collaborations and Partnerships

Collaborations between industry players and academic or research institutions are essential for fostering innovation. These partnerships allow for knowledge sharing, access to cutting-edge technologies, and the development of tailored solutions. Collaborative research projects are multiplying, with promising results for improving stamping and cutting processes.

10. Customization and Production Flexibility

The growing demand for customized products is driving companies to adopt more flexible production methods. Stamping and cutting systems must quickly adapt to various designs and production volumes. Modular solutions and flexible production lines address the need for customization and agility.

The trends in stamping and cutting for 2024 clearly show that the sector is undergoing significant transformation. Technological innovations, the integration of new methods, and the emphasis on sustainability and flexibility are key elements of this evolution. To remain competitive, companies must embrace these trends and invest in cutting-edge technologies and skills.

Learn More

For more information about innovative solutions in stamping and cutting, visit our Stamping and Cutting

A certified quality partner

for the overall management of your projects

Comprehensive solution

From the prototype to the delivery of series parts to the client

Tailored production

Medium and large series

50 years of experience

30 people at your service - recognised know-how and expertise

Certified quality

Certification according to ISO 9001 and IATF 16949