Efficiency, excellence, and innovation are the pillars of the home appliance industry. Precision sheet metal contributes to the manufacture of reliable and high-performing household appliances. Their operation and longevity largely depend on these metal components.

In this article, we will explore why precision sheet metal is essential for the home appliance sector, highlighting examples of parts produced by Ouréval for a client.

The Backbone of Home Appliances

Imagine opening the door of your dishwasher, turning on your oven, or cooling your food in a refrigerator. Each of these actions is made possible by a complex series of metal parts forming the backbone of these devices. This is where precision sheet metal comes into play.

This manufacturing process involves cutting, bending, stamping, welding, and assembling metal sheets to create components used in various industries, notably home appliances. The use of CNC machines, specialized tools, and advanced techniques allows for the production of parts with exact dimensions meeting the highest quality standards.

Below are concrete examples of parts produced by Ouréval for a home appliance industry client:

Filter Frame

The frames secure the filter to remove impurities, debris, or unwanted particles. They ensure the cleanliness, safety, and proper functioning of household appliances such as:

- Dishwasher: to retain food particles and debris during the wash cycle.

- Washing Machine: to capture lint and small objects that could clog the pipes or drain pump.

- Vacuum Cleaner: to trap dust, allergens, and fine particles, ensuring cleaner expelled air.

- Air Purifier: often equipped with HEPA filter frames to remove fine particles from the ambient air.

- Kitchen Hood: may have grease filters acting as frames to capture cooking grease and particles.

- Domestic Air Conditioner: to purify the ambient air.

- Humidifier/Dehumidifier: to improve air quality with filters housed in filter frames.

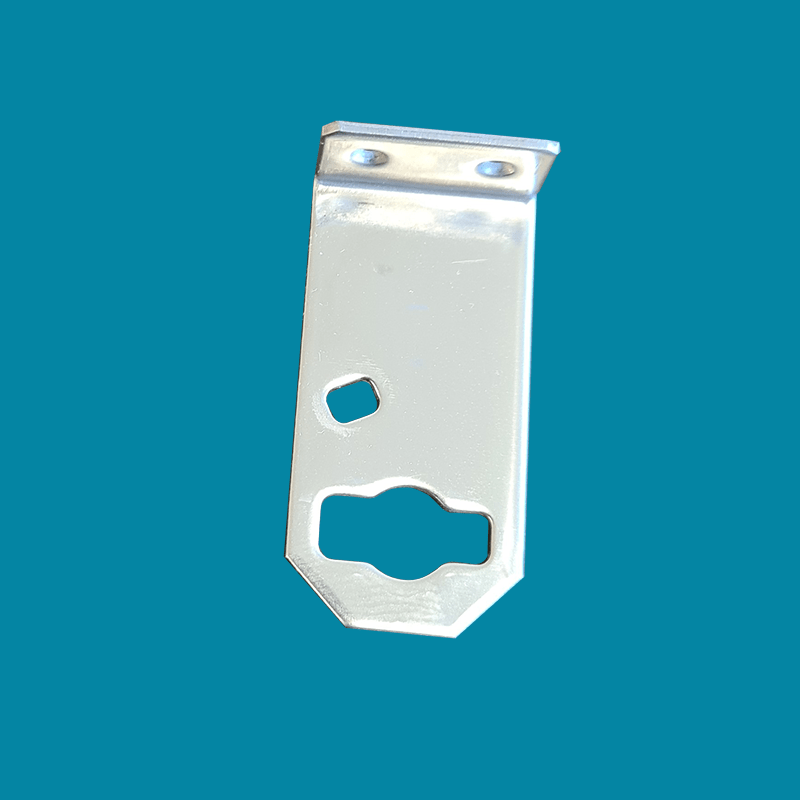

Bracket

Brackets serve several functions: reinforcing the structure, holding components in place, or ensuring stability. They are versatile and used in a variety of home appliances, including:

- Refrigerator and Freezer: to reinforce shelves, drawers, or internal supports.

- Dishwasher: to support cutlery baskets or upper shelves.

- Stove and Oven: to reinforce shelves, grill supports, or internal heating elements.

- Washing Machine and Dryer: to reinforce the internal structure and hold the drums in place.

- Microwave: to support turntables or other internal components.

- Kitchen Hood: to reinforce the hood structure or support grease filters.

- Microwave Oven: in some models, brackets support the turntable, ensuring smooth operation.

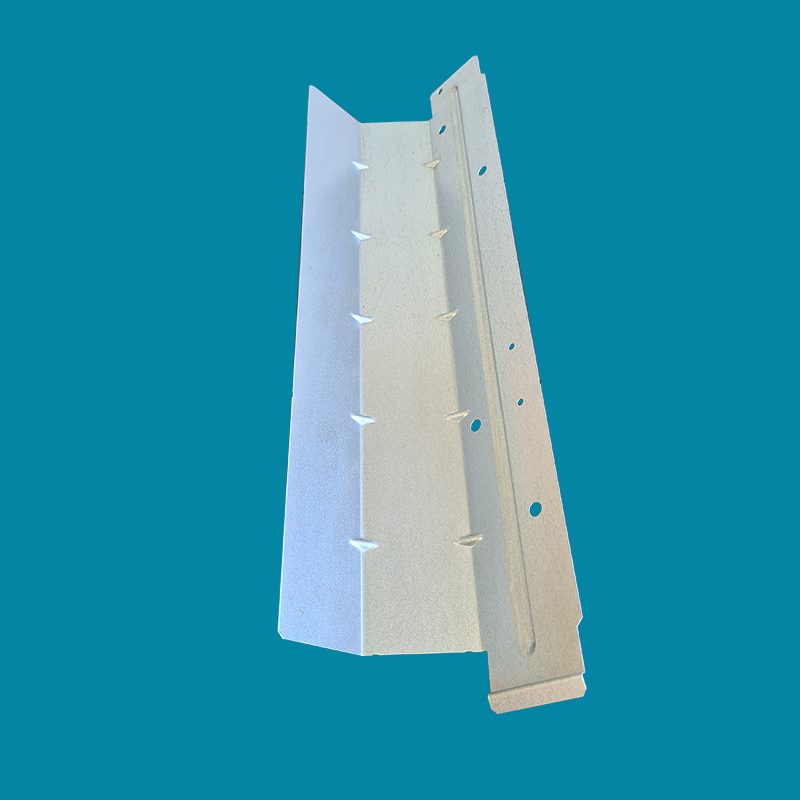

Deflector

Deflectors direct the flow of air or heat optimally. They ensure efficient energy use and provide maximum comfort and functionality for the user. You can find them in the following appliances:

- Air Conditioner and Heating System: to direct hot or cold air in different directions, ensuring even distribution in the room.

- Fans: to control the direction of airflow.

- Dryer: to direct hot air through clothes for uniform drying.

- Oven and Stove: to ensure even heat distribution inside the appliance.

- Kitchen Hood: to direct smoke, vapors, and cooking odors outside.

Beam

Beams reinforce the structure of the appliance and support internal components. They ensure the stability and solidity of the appliance while maintaining the proper functioning of internal components. Here are some examples of home appliances with beams:

- Washing Machine: to support the drum and keep it in place during the wash and spin cycles.

- Front-loading Dryer: to hold the drum in position and support the weight of clothes during drying.

- Refrigerator: to reinforce shelves or internal supports, especially in freezer compartments.

- Oven and Stove: to support grills, cooking plates, and other internal components.

- Microwave: to support the turntable and ensure smooth operation.

- Dishwasher: to hold cutlery baskets or upper shelves in place.

- Freezer: to reinforce the internal structure and support shelves and storage compartments.

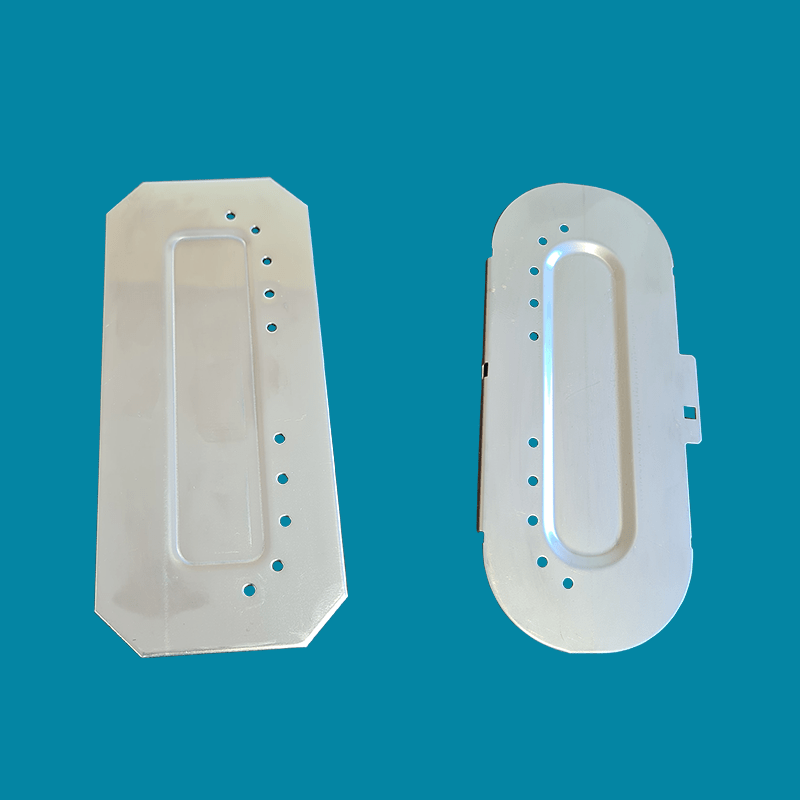

Flap Cover

Flap covers are commonly used in household appliances for easy and quick access to the interior. They are designed to simplify the use of appliances, adding ingredients, accessing storage compartments, or performing maintenance operations while ensuring user safety. Examples of appliances with flap covers:

- Dishwasher: for accessing the detergent or salt compartment.

- Washing Machine: for accessing the detergent or softener compartment.

- Coffee Machine: for accessing the water tank or ground coffee compartment.

- Oven: to facilitate access to the utensil storage compartment.

- Stove: for accessing the storage compartment or cutlery drawer compartment.

- Etc.

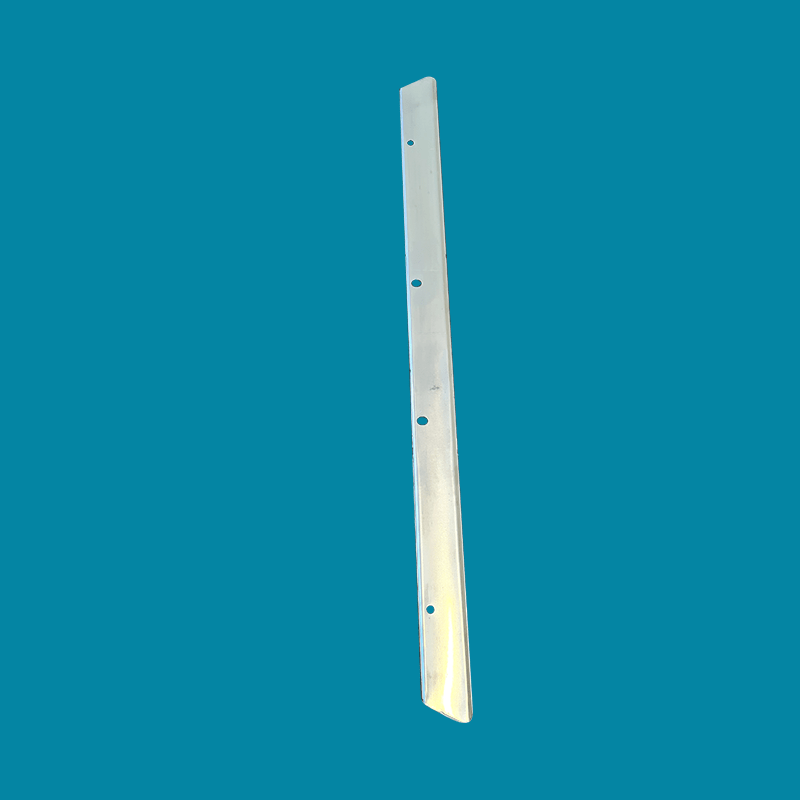

Connector Bar

This type of bar ensures reliable and secure electrical connections between multiple wires. Widely used in the home appliance sector, it contributes to the proper functioning and safety of the appliances. Here are some examples of devices with connector bars:

- Washing Machine and Dryer: to connect the wires of motors, sensors, heating elements, and control components.

- Dishwasher: for the wires of pumps, heating elements, sensors, and control devices.

- Stove and Oven: for connecting wires of heating elements, thermostats, resistors, and switches.

- Refrigerator and Freezer: the bars are used for internal electrical connections, including compressor motors, defrost devices, and electronic controllers.

- Microwave: to connect the wires of the magnetron, lamps, fans, and other electrical components.

- Vacuum Cleaner: to connect the wires of the motor, switches, power buttons, and other electrical components.

- Etc.

Flap

Flaps are generally used to regulate the flow of air, water, or other elements essential for the proper functioning of appliances. Here are some examples of use:

- Dishwasher: to control the water flow into the machine. They can be adjusted to modulate the water amount required for different washing cycles based on the type of dishes and level of dirt.

- Refrigerator and Freezer: to regulate the air flow inside the appliance. They maintain uniform temperatures and prevent frost formation in the freezer compartment.

- Ventilation System: ventilation systems like kitchen hoods can be equipped with exhaust flaps to direct vapors, odors, and heat outside the kitchen.

- Microwave Oven: to direct microwaves uniformly towards the food, ensuring even cooking.

Other Examples of Home Appliance Parts

Many other types of precision sheet metal parts are manufactured for the home appliance sector, including:

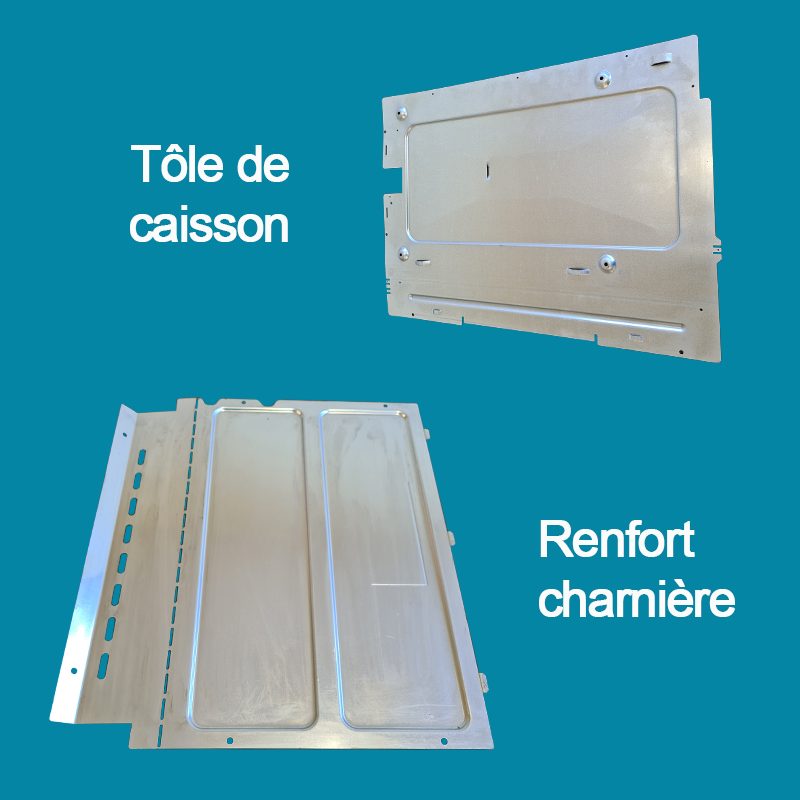

- Casing Sheet: to insulate and reinforce the structure of many appliances, particularly refrigerators and freezers.

- Fixing Sheet: to hold components in place, ensuring the proper functioning of the appliance.

- Hinge Reinforcement: to improve the stability and durability of hinged doors in various appliances.

- Motor Support: to ensure precise and stable positioning of electric motors, contributing to the overall performance of the appliance.

- Etc.

Ouréval: Your Trusted Partner in Precision Sheet Metal

Since 1973, Ouréval has been renowned for its expertise in cutting, stamping, designing, and manufacturing press tools. We stand out as a partner of choice for several reasons:

- Press Tool Design: Our design office located in Villé, in the Grand Est region, is committed to developing and monitoring progressive tools. To ensure unmatched cutting precision, we take responsibility for the maintenance and sharpening of our press tools internally. We provide our clients with a conformity guarantee for all parts, whether produced in medium or very large series.

- Advanced Production Management: Orders are directly integrated into our management system through Electronic Data Interchange (EDI) technology. This integration allows us to optimally manage our orders, stock levels, and raw materials.

- Quality Certifications: Ouréval holds ISO 9001 and IATF 16949 certifications, demonstrating its commitment to quality and continuous improvement. Each part produced by Ouréval adheres to strict quality standards, ensuring the reliability and durability of the final household appliances.

In conclusion, precision sheet metal is an essential link in the home appliance production chain. The assembly of these metal parts ensures the performance and longevity of household appliances. Ouréval is committed to supporting you in your cutting, stamping projects, and custom tool design. The next time you use your dishwasher, oven, or refrigerator, take a moment to appreciate the precision work that created these invisible but crucial parts that compose them.

A certified quality partner

for the overall management of your projects

Comprehensive solution

From the prototype to the delivery of series parts to the client

Tailored production

Medium and large series

50 years of experience

30 people at your service - recognised know-how and expertise

Certified quality

Certification according to ISO 9001 and IATF 16949